Bespoked 2024, Manchester UK - The Highlights

Roving reporter Chris Keller-Jackson dived in at Manchester's 'Vicky Baths' venue on June 28 and found that while the spirit of innovation and progress is alive and kicking within the UK bike manufacturing scene, it's balanced with a respectful nod to the ground on which the modern industry stands.

For 13 years the UK’s Bespoked show has been drawing in crowds: crowds of bicycle enthusiasts; crowds of bespoke and small-scale manufacturers and niche component builders; and as Brexit began to bite deeper, last year the show branched out to draw crowds at a very successful detour in Germany.

In its post-Covid life, under new management after the Taylors handed it off to Petor Giorgallou formerly of Dear Susan Bicycles, Bespoked tried a Harrogate venue in 2021, which was a bit cramped, then London last year at the Olympic Velodrome site, far from the city buzz and a bit clinical, and now in 2024 Bespoke lands in Manchester, within spitting distance of ‘The Home of British Cycling’, Manchester Velodrome / The National Cycling Centre.

When I first heard that Bespoked would be in Manchester and they were looking for a suitable event space, I knew it didn’t warrant a shed or a soulless box to show off these beautiful products. I'd hoped it would be one of two venues, Victoria Baths being one.

One of the three show halls in the Manchester venue—note the changing cubicles along the sides. This was shot on Press Day, so no crowds

‘Baths’ is what us Brits call a Swimming Pool, this one is vintage. It opened in 1906 and comprised three swimming pools in a decidedly Victorian style: wrought iron, changing rooms around the pools, splendid tiles in aqua greens and blues, large staircases, and Victoriana everywhere. Perfect for an event space with vibrant, slightly decaying beauty to juxtapose against modern underground bike culture. It doesn’t currently have water in the pools, instead the those are the event spaces.

There was a third show hall about this size, and some other small rooms. That's enough of the venue shots...

As a side note, Vicky Baths is no stranger to cycling, In 2011 I was the Red Bull photographer for ‘Minidrome’ when a wooden velodrome was built within the main pool, where combatants rode against the clock and each other, sometimes being caught, sometimes colliding and sometimes flipping off the edge. A great use of the venue back then, and now this.

The future will always be mass-market bikes, but there is wonder and delight in seeing this diversity, this quality, this uniqueness in an often bland and cookie-cutter market place. There is plenty here to wonder at, to lead the mass market, not just super fast exotics, or simple solutions to lingering problems, and not just exquisite painting. This venue, these bikes, are the antithesis of conventional bike trade show—and a perfect match for each other.

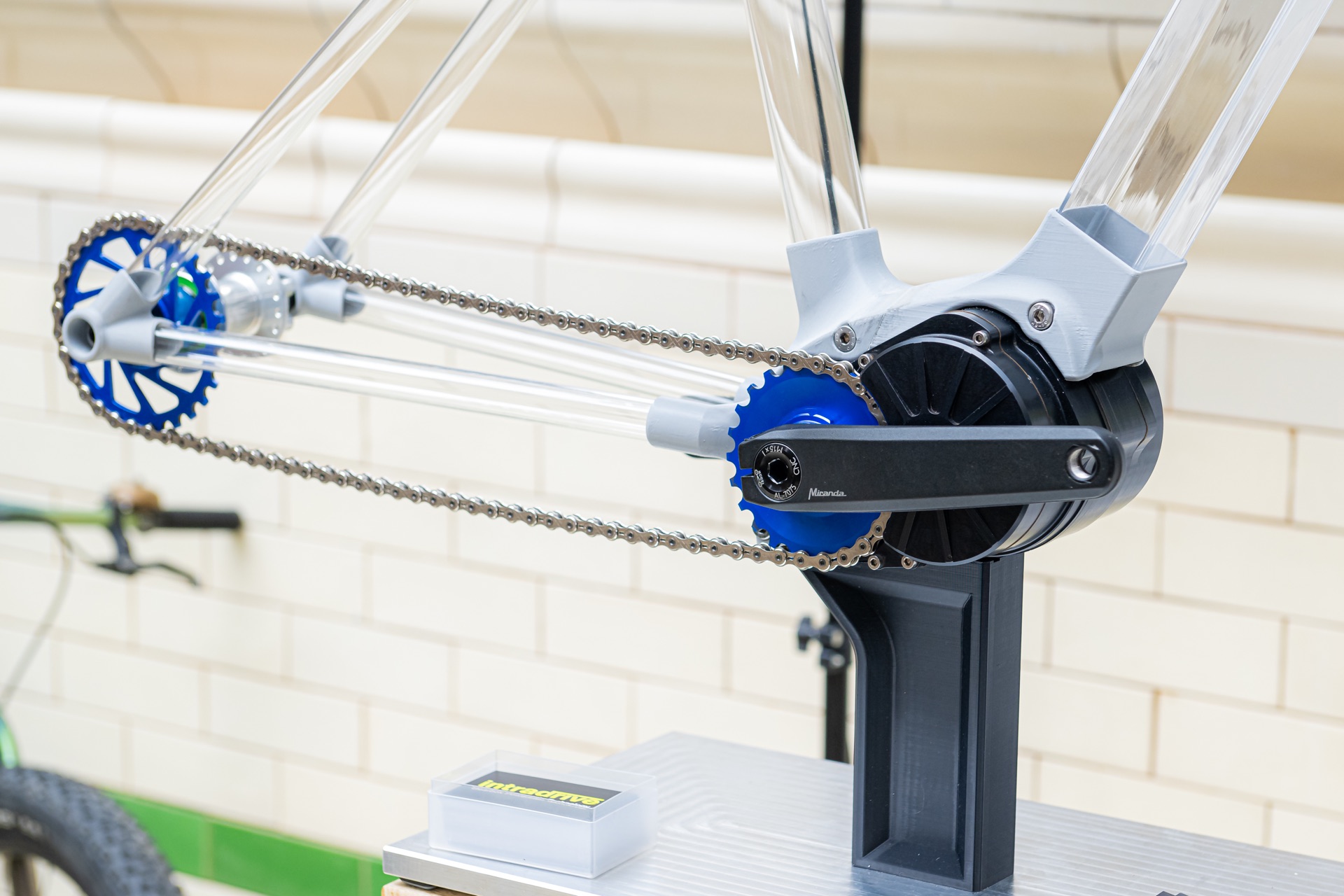

They burned the midnight oil at Eighteen Bikes getting this mid-drive eMTB frame ready. Don't we all love the hard deadlines of bike shows?

Starting with something unique and innovative from Eighteen Bikes, this is exactly what this show is about. It was only finalised this morning, it's not for sale yet, and ‘finalised’ in this case means it has no forks, no derailleur or seatpost—not even a headset. Eighteen Bikes is a tiny bike shop, workshop, and framebuilder based in the Peak District, right in the heart of the Pennines (the hilly bit in the central spine of England). Riding, fixing and making bikes is what they do. But not full suspension, and not eMTB’s. Well they do now, though it doesn’t really have a name (other than ‘Prototype’), and nor have they been ridden.

The fully assembled bike, rear, is an acoustic version of the eMTB at front

MTB’s are not the staple of Bespoked, nor are eBikes, so the combination of the two, and its analogue cousin behind, are a little unusual—especially so fresh from the welders—like homework displaying all the roughness of the working out. Let’s be clear: These bikes are one-off’s and may never make it to the market in this exact form. The letters P R o t o t y p e are also freshly adhered, so’s not to confuse show-goers that the high idler is in the right location, the chain stays are the correct length, and even that the power plant is actually available. Innovation is great, and the team behind both bikes can’t wait to get on board, so I ask if the bike will be available as a frame-only purchase. I’m given a skeptical look of ‘are you mad?’ Eighteen staff explain the legalities around eBikes might mean legislation dictates minimum fork strengths, wheel types and other parameters that can only come from a full-build package. So, Eighteen Bikes prototypes: Raw, innovative and beautiful in concept.

Leo from KoM with their dual axle ‘Infinity Drive’ Zeno hub

Just down the pool, and just up the road geographically from Eighteen is ‘KoM’ (King of the Mountain) which displayed Zeno, a radically different take on hub design. Inside a freewheeling cassette body, the freewheel is at the disc end, and the disk helps secure the pawls. There are two concentric axles inside the hub body. I know: it can’t work, but reportedly it does.

The idea of a freewhel on the disc side has some obvious advantages. We'd love to try the Zeno hub for an extended period to see how it feels and holds up

Advantages are bigger bearings in the hub shell, and no overhanging cassette supported on tiny bearings. The hub shell and cassette body are one unit, minimizing flex and axle distortion. KoM claims reduced drag, better bearing life, and less axle flex. Rider feedback, they say, is very positive so far. This is excellent design for manufacturing, with many components doing dual duty.

Also in the KoM booth was a custom Hope HB916 Enduro Bike build on display, in a fetching purple colour scheme

If eBikes are everywhere, so are cargo bikes—in towns and cities at least. London based Assembly Bikes hand-make cargo and eCargo bikes with clever, sturdy frames and cantilever load beds which, wide when in use, rotate out of the way for convenient bike storage. This may seem like a minor detail, but given the limited spaces of city dwelling it could be the deciding factor in buying one or not.

Jim from Assembly Bikes showing flipped-up rack, and bars rotated for narrower storage. Love this!

Now dabbling in eCargo, Jim has some thoughts on modularity to increase the functional life of frames, going away from rear hub motors, and providing an interchangeable cradle to support different mid-mounted motor units.

e-power for cargo bikes makes a lot of sense. Orange levers on the rack rotate for narrow storage mode

Part of the company ethos is sustainability and repairability to give longevity to workhorse bikes, and manage the change in standards and technology.

Beautiful isn't it? We're betting photo's of this bike will travel the world

TWMPA is a manufacturer in Wales making bike frames out of European Ash. I first saw their beautiful bikes two years ago at the Harrogate Bespoked show, and this time Andy Dix brought something I never expected to see. Part of the allure of a TWMPA wooden bike is the beautiful patterns, the textures and grain within the wood, plus the engineered fit of the morticed and glued joints. So why is the hero bike on the stand painted? Andy tells me that some viewers only comment on the wood, not the bike and not the ride, and to offset this feedback, he decided to have one painted.

Genius paintwork: Apply semi- transparent thinned paint, add clear-coat, then let the wood grain do the rest!

Looking closer, you can still see the grain under the beautiful frame paint, and wood behind the logo and head badge is left naked, just clear-coated.

Ride reviews in the cycling press have praised this as an impressively compliant frame, and each bike is designed around the rider’s needs. Hopefully Twmpa will start to offer this exotic frame colour treatment option to customers. And In case you’re wondering about the name, Twmpa is the name of a Hill at the southern tip of the UK’s Black Mountains, just inside the Welsh border.

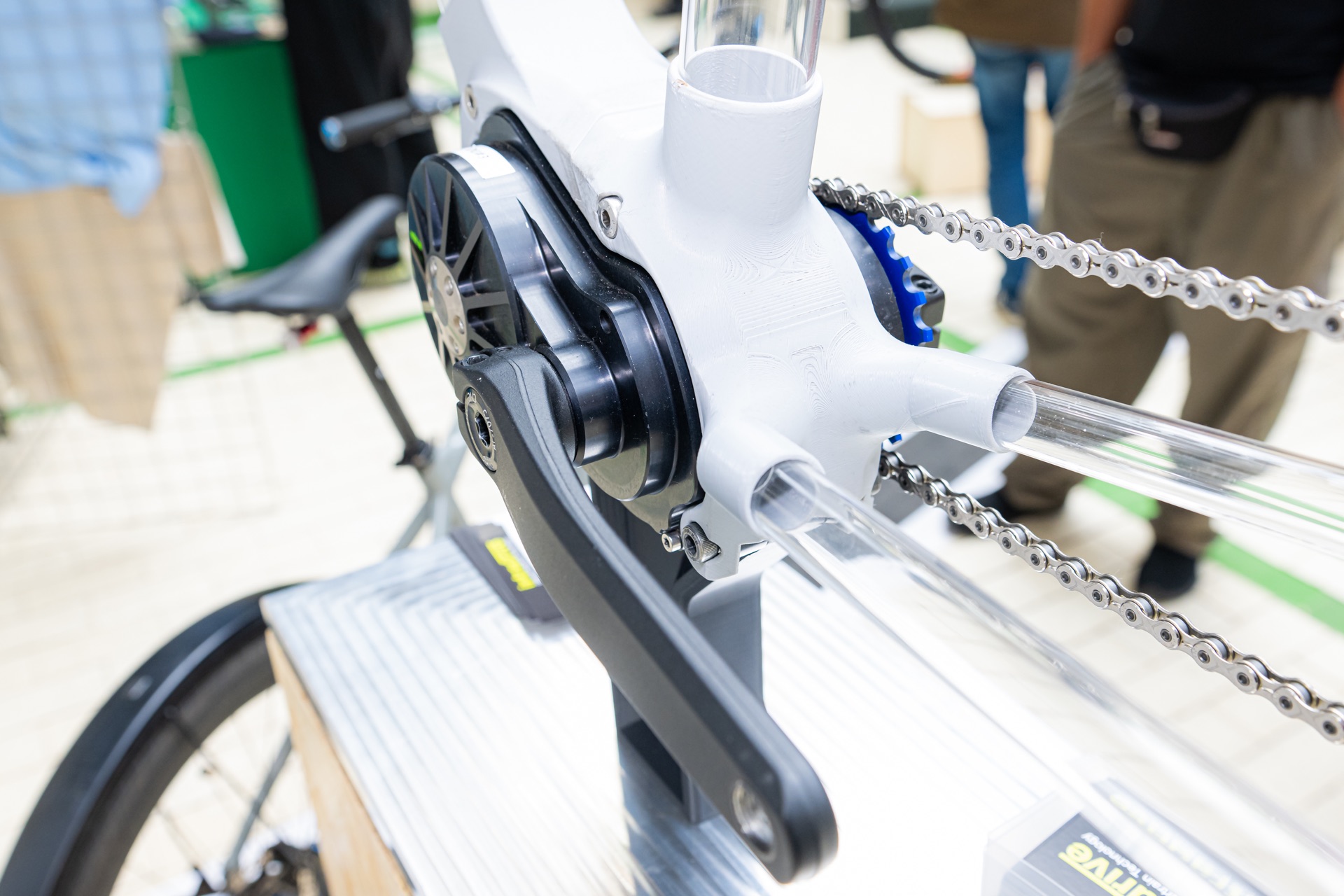

Intradrive's black casing houses an electric motor and gearbox with sequential gear change mechanism in a beautifully compact form factor

Another example of the technological development that has kept UK cycling manufacturers at the forefront of bicycle engineering over the decades comes from Edinburgh-based brand Intradrive. This company produces electric powertrains with integral sequential gearboxes built into a standard shell designed to fit Shimano EP8 mountings.

It looks pretty good from this side, too

The product comes as a belt or chain drive motor unit, as well as a transaxle unit for three and four- wheeled ‘last mile’ vehicles. Intradrive had fitted their powertrain to several different bicycles on display. The one I could’t walk past was a low-slung cargo model built in partnership with Olsen bikes. Front wheel hub-steering, negates the traditional fork mount for a super-clean front end, with the Intradrive system powering the rear wheel.

Just begging to be ridden, isn't it? And take a good look at that front hub steering mechanism

Intradrive powertrain technology comes as an all in one package, with battery, controller, wiring and drive unit developed to be repairable, environmentally sealed and having extended maintenance periods. I’m keen to see this technology make it to commercial success, they are ready to go.

Steel and Titanium were on display almost everywhere you looked. Reilly Cycleworks from Brighton offer beautiful frames and bike builds for road and gravel, and always produce show stopping custom colours for their show bikes.

The Jigsaw inspired Fusion and Reflex bikes looked resplendent in bare Titanium and Burnished purple, gold and blues.

New is great, but this paint scheme will bring back fond memories to those who were there back in Monty Young's day

More beautiful bikes come from the home of Condor Cycles, making custom frames in London since 1948. With lots of bikes on display, the standout is the Condor themed Super Acciaio + Trittico with custom painted Columbus Trittico integrated Carbon Handlebar, part of a fully integrated setup with smooth lines and fully hidden cables. A tribute to the master craftspeople who design and manufacture these beautiful bikes in Italy and a perfect bike for Bespoked.

Condor have a great race heritage as well as in courier bikes (one of which was ridden by HBG’s founder in London during the 1980s - Ed.). The company is soon to launch a fixie/courier frame to their same exacting standards - I can’t wait to see builds of that.

The world of Bespoked includes plenty of accessory brands, partly because of the utility inherent in bespoke bikes, partly to make a custom bike more distinctive and partly because top end racers often use one-off and pre-production frames in racing. In the case of the emergence of gravel and ultra-distance, load management has undergone much re-design.

Tailfin, based in Bristol, UK, are at the forefront of this emergence, and whilst their offering comes from the Henry Ford palette, their use of fabric welding, sustainability and mounting point solutions is on-point. Lachlan Morton recently won the Unbound Gravel race using Tailfin products, a testament to the hardwearing approach taken to design and product functionality.

You might see some spy shots of future products on the depicted bike (plus some hand customisation from one of the designers) - I couldn’t possibly tell you any more about the handlebar bags properties. Look away please.

A different approach to Bikepacking is taken by Wizard Works from London, a colourful and more protective proposition, and a modular approach befitting a less racy brand. Great for commuting and transitioning from bike to walking. In the ‘offseason’ the small team at Wizard can accommodate collaborations and have had successful cooperation with brands such as Stooge Cycles, Raeburn and Brother Cycles. With a sustainability focus and an winter high visibility range, as well as customisation options, Wizard Works compliment Bespoked well.

Steve Peat really started something back in the '90s...

Atherton Bikes may seem like an outlier at Bespoked, but customisation is at the heart of what they do. The ability to create a bike to your exacting standards through additive manufacturing and selected custom lengths of carbon tube is not something every downhill bike manufacturer can do, certainly not for the masses. Pro racers on other brands sometimes have access to customised bikes, but with Atherton Bikes, all the carbon-tubed bikes can be custom printed to the rider’s needs. On display was the current range, including the newest addition, the S Range (alloy framed) bikes plus (pictured above) the bike used by Charlie Hatton to win the World Championships in 2023 at Nevis Range.

Gary Ewing on his bike for people who like lots of linkages... and unified rear triangles

Here’s another take on what is bespoke. If your thing is: Only 3 bike iterations in the design process, Lego blocks used to check frame kinematics, and 20+ bearings in the rear suspension and drivetrain, then read on. You might think that Auckland Cycle Works had travelled across the globe to be here, but it turns out it’s Bishop Auckland in the North East of England. This story started when Gary Ewing from Inspire Cycles spent some time riding with ultra-distance maestro, the late Mike Hall. Mike mentioned something about unified rear triangles had yet to be explored, but he couldn’t put his finger on it. This sparked an idea with Gary that sometime later morphed into a patented dual co-rotating suspension design including a unified rear triangle with braking anti-rise.

Hands up who wants to see the video of Auckland using Lego to check these frame kinematics

Check out the bike kinematics and the idea behind the suspension performance on the Auckland Cycle Works site. Very interesting and truly bespoke. This booth had a prime spot and was constantly busy with people enquiring about the bike on display.

The Son booth was another place to go for pre-production spy shots at Bespoked. The ultra-distance dynamo and power provider showed the not-yet-available SON 29 S dynamo hub. It’s tiny, like front-hub-with-a-large-flange tiny. Son claims it is less laggy, and therefore an efficiency bonus when you are covering the long miles.

The world leader in dynamo lighting tech also displayed their integrated cockpit and charging solution with magnetic charging leads and Edelux light, a very neat solution to what can be a complicated problem of power storage and usage.

Company name notwithstandng, this looks like a pretty sweet ride

No event calling itself a European Bike Show would be complete without a smattering of actual (not mentioning Brexit again!) European producers. Hailing from the Saxony region in Germany, Sour Bikes brought their hardtail MTB/Adventure bike—the Pasta Party—in a fetching matt purple.

Some lovely clean lines in a compact frame. It has an almost hidden eccentric bottom bracket, and a race-ready Steel frame.

Highlights on this bike are the new Fox 32 Step Cast Rear Arch Matrix fork, INGRID rear mech and cassette and the stealthily hidden INGRID TTS Thumb Shifter.

The cornucopia of bikes and parts makers, the vibrancy, passion, and in particular, innovation, are the key strengths of Bespoked, and the whole hand built community. There was so much to see and talk about in this great location. I’m already looking forward to the next time it’s here. And put this in your diary: Next stop for Bespoked, Dresden in October.

Editor's note: At HBG we take a worldwide view of the framebuilder and small manufacturer industry. Thus it serves us to keep track of the respective show sizes and compositions. Exhibitor specifics weren't available at the time of publication, and the Bespoke website doesn't distinguish between the Germany and UK shows in its exhibitor list. We reckon between 40 and 50 exhibitors were at the Manchester show, with about five of those from outside the UK. This is considerably smaller than the pre-Covid years, although the percentages might be similar. What might happen in the future is anybody's guess, but with the EU frame builder scene now very active in several countries it could be seen as developing to become the worldwide hub of the industry, or at least a solid counterbalance to the resurgent US scene. We will be keeping a close eye on Bespoked Germany in October. Here is a link to our international calendar of events.